Benchmarking

Our benchmarking services focuses on the following two segments:

- Hardware benchmarking:

GETEC is capable of analysing the powertrain structure and its layout in the vehicle, component dimensions and materials, as well as their functionalities within shortest time. - Driving evaluation:

GETEC professionals drive the vehicle in all possible conditions. The measurement data is used and evaluated to develop requirements for customer developments.

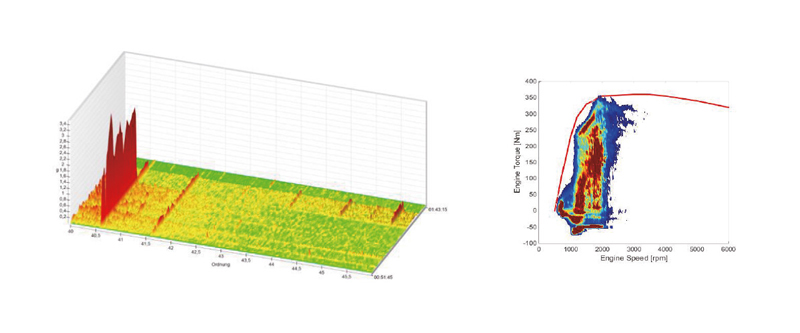

Road Load data (RLD)

Our Road Load Data (RLD) Acquisition and Evaluation Tool enables customers to generate lifetime damage representative CAE duty cycles, bench test cycles and vehicle test programs.

The RLD service includes the following steps:

- RLD Planning (target setting, measurement location & content planning, definition of required measurement signals, driver characteristic planning).

- RLD Preparation (vehicle preparation, sensor installation / CAN decryption by GETECs’ DecodeIt Tool, vehicle approval, logistics).

- RLD Conduction (RLD measurements on real road, on test track and in special environment or locations).

- RLD Evaluation (duty cycle, test bench test cycle, vehicle test program and test specification development).

Signal Acquisition

- Our application engineers have accumulated huge experience in vehicle CAN, UDS, Flexray analysis, testing and reverse engineering.

- Standardized and specific tools are applied to quickly obtain complete vehicle information and use it for summary and analysis for customer feedback.

Calibration

Combined with our extensive calibration experience, GETEC can provide the following calibration services:

- Shift quality and strategy benchmarking

- Calibration development and assessment

- Shift map and strategy calibration

- Calibration and optimization of garage shifts, creep, launch, shifting, slope, deceleration, diagnostics

- Interface check

- Single shift quality deep drivability analysis

In the calibration, GETIT SimuDrive tool that developed by GETEC is mainly used for:

- Fuel consumption simulation(NEDC/WLTC cycle etc.)

- Performance simulation

- Acceleration performance

- Re-acceleration performance

- Drivability simulation

- Acceleration(from standstill)

- Acceleration(from constant)

- Saw Tooth &Tip in(Busy shift check)

- Real Road Cycle(eg. Typical drive cycle from RLD)

- Generating and optimizing shift map

- ECO shift map/Sport shift map

- Pedal map checking and optimizing

NVH

GETEC has many years of experience in NVH optimization and problem solving of different drivetrain systems, providing comprehensive solutions to the problems of traditional drivetrain and new energy drivetrain NVH.

For more details and requires, please contact with our team.

We will reply you once we get your message.

For Europe Market, please contact:

Mr. Michael Spielmann

Key Account Manager

+49 2464 90266 266

michael.spielmann@getec-gmbh.com

For Asia Market, please contact:

Mr. Xia Shaohua

Project & Business Director

+86 512 6895 2081

shaohua.xia@getec-gmbh.com